Solenoid for Trunk Mounted battery

Moderator: Site Administrators

-

dangina

- GTX (RS)

- Posts: 380

- Joined: Sat Feb 12, 2011 12:28 am

- My Cars: 71 roadrunner

- Location: lethbridge, ab

Re: Solenoid for Trunk Mounted battery

sounds good! I was going to stick with a 383 as well until the wife gave me the green light to build what I wanted. 400 stroked to 470. Not too big, not too small. Just the right amount of reliablilty and driveability :0) what cam you putiing in? is it a stock 383 build? I was gonna purchase the whiplash cam up until I went stroker.

400 stroked to 470ci, 3:55 Eaton true trac, slightly upgraded suspension lol

BUILD THREAD!!!! http://www.protouringmopar.com/showthread.php?796-1971-Speedipus-Rex&highlight=speedipus

BUILD THREAD!!!! http://www.protouringmopar.com/showthread.php?796-1971-Speedipus-Rex&highlight=speedipus

- road chicken

- GTX (RS)

- Posts: 660

- Joined: Thu Oct 09, 2003 11:21 pm

- Location: SE WI

Re: Solenoid for Trunk Mounted battery

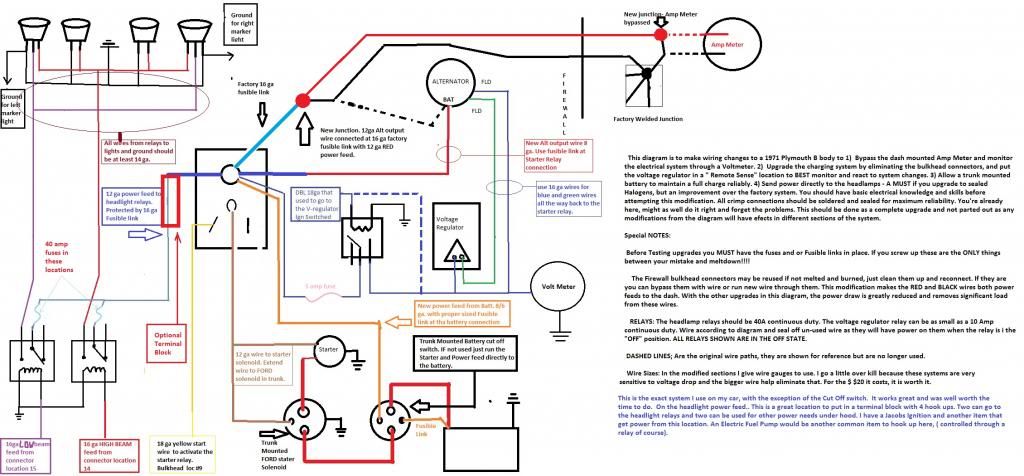

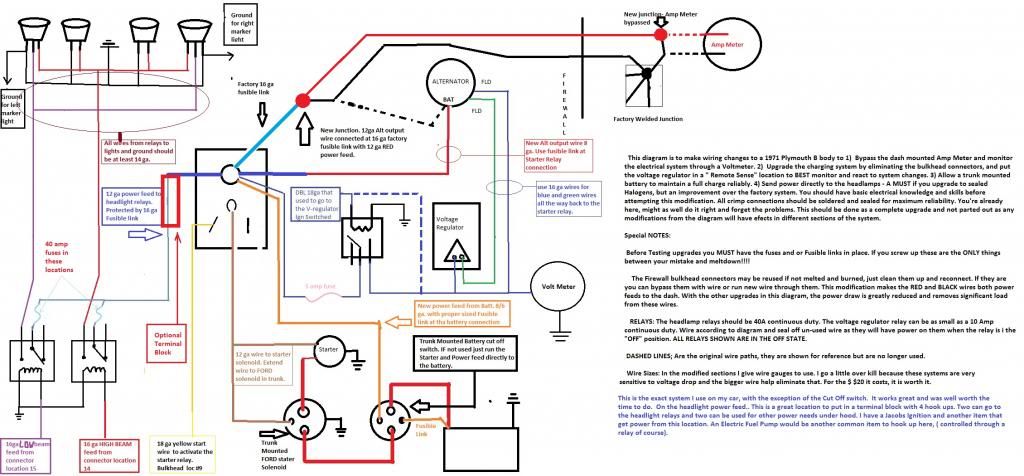

Hey I actually got it done LOL and POSTED- The world has shifted. Ok take a look and how it works. It might be easier to go to my Photobucket page and read it, or save it and open it with windows Photo Viewer to Magnify the picture.

http://i1272.photobucket.com/albums/y39 ... df8022.jpg

http://i1272.photobucket.com/albums/y39 ... df8022.jpg

Last edited by road chicken on Thu Apr 10, 2014 2:01 pm, edited 1 time in total.

4th generation B bodys- there is no substitute.

68 383, Street Demon 750, RPM top end,484/284/108 poo poo cam "-5 spd 4:10 SG, 4whl disk, Helwig Anti-Sway, Poly bushings,Firm Feel Box, HD Linkage, 1" t-bars, 7 leafs Springs

68 383, Street Demon 750, RPM top end,484/284/108 poo poo cam "-5 spd 4:10 SG, 4whl disk, Helwig Anti-Sway, Poly bushings,Firm Feel Box, HD Linkage, 1" t-bars, 7 leafs Springs

- road chicken

- GTX (RS)

- Posts: 660

- Joined: Thu Oct 09, 2003 11:21 pm

- Location: SE WI

Re: Solenoid for Trunk Mounted battery

I'm "THAT" guy who wants my car to do everything well, using stock parts whenever possible and being a bit of an underdog always has it's appeal. Anyway, in that scheme the 383 just stood out as a Thoroughbred of engineering and a great balance to achieve my goals. I'm using the MP 484/284/108 cam. I had it on the shelf and it fits perfect with the rest of the cars equipment. I have a 30 over block with a 9.2:1 measured compression ratio, built to handle 6500 rpm all day long. A little soft so the bottom end issue is magnified slightly, but I can run pump gas. It's offset by the gearing which, with the tremec 5 speed I have, gives me a 5.05 effective rear end in 1st gear and 4.10 gears 2nd - 4th, and an effective 2.78 in 5th gear. The cam gives me about as much lift and duration as I dare and keep a margin of safety if I blow a shift. Doesn't happen often, but just in case. It also meets a standard of the not having a split duration which is important because I'm using port matched stock HP exhaust manifolds. I saw a build up a while back that had a 400 stroked to a 466, using the same top end with the exhaust manifolds. The cam they had was the MP mechanical .528 solid lifter cam. ( slightly more aggressive ramp rate on the cam with a wider centerline- 112 or 114- I think). Anyway-these jokers got 474-460 HP at the real wheels on a stick car. The split duration cams actually cost HP with the manifolds. So if I figure this right, I should be able to put down 360 to the rear wheels, and be able to pull 18 mpg on the highway. I actually got 20 MPG when I had the 4 speed and 3.23"s at 60 mph with this cam before, but it is such a pooch off the line. Now it should get into the powerband like RIGHT NOW and stay there, which is the key for running a 383. It's ok to highjack my own thread ....right?dangina wrote:sounds good! I was going to stick with a 383 as well until the wife gave me the green light to build what I wanted. 400 stroked to 470. Not too big, not too small. Just the right amount of reliablilty and driveability :0) what cam you putiing in? is it a stock 383 build? I was gonna purchase the whiplash cam up until I went stroker.

4th generation B bodys- there is no substitute.

68 383, Street Demon 750, RPM top end,484/284/108 poo poo cam "-5 spd 4:10 SG, 4whl disk, Helwig Anti-Sway, Poly bushings,Firm Feel Box, HD Linkage, 1" t-bars, 7 leafs Springs

68 383, Street Demon 750, RPM top end,484/284/108 poo poo cam "-5 spd 4:10 SG, 4whl disk, Helwig Anti-Sway, Poly bushings,Firm Feel Box, HD Linkage, 1" t-bars, 7 leafs Springs

-

dangina

- GTX (RS)

- Posts: 380

- Joined: Sat Feb 12, 2011 12:28 am

- My Cars: 71 roadrunner

- Location: lethbridge, ab

Re: Solenoid for Trunk Mounted battery

doh! I just saw your post now, didn't realize you had it up 4 days ago! IS the relay in the middle a continous duty relay? I had a hard time reading some of it, I just may need glasses. I'm also gonna try eliminate any fusable links and use fuses instead. I hate them, PITA to change and you have to meter them to tell if thier dead. Also with the ammeter red and black wire through the firewall I 'm just gonna eliminate those 2 small wire and use a big one like a 6awg to a bulkhead connector, and from the bulkhead connector to the the black wire feed junction. Gonna use something like this:

400 stroked to 470ci, 3:55 Eaton true trac, slightly upgraded suspension lol

BUILD THREAD!!!! http://www.protouringmopar.com/showthread.php?796-1971-Speedipus-Rex&highlight=speedipus

BUILD THREAD!!!! http://www.protouringmopar.com/showthread.php?796-1971-Speedipus-Rex&highlight=speedipus

- road chicken

- GTX (RS)

- Posts: 660

- Joined: Thu Oct 09, 2003 11:21 pm

- Location: SE WI

Re: Solenoid for Trunk Mounted battery

Actually I'm re doing the whole thing in a bigger size. I thought the MS PAINT program would copy better than it did.

All the relays are continuous duty, with the exception of the Starter relay ( which isn't marked but has all the power feeding to it-) and the Ford Solenoid in the trunk. The Headlamps are 30-40 amp rated and the Voltage Regulator is 10 amps. It won't ever see that much but the Headlamps will draw @ 20A ( my best guess,since figured it out yet). ( lets see 4 - 55w bulbs = 220 watts/ 12 volts = 18 amps) so yes a 30 amp should give you a %50 margin of safety/ reliability.

You'll have to do the research on the fuses since I don't know what the proper ratings should be. With the links- they should either work or blow into oblivion. I never heard of them being spotty- but that doesn't mean it couldn't happen.

The wire feed through s: Not really necessary- you can if you want, but since the red and black become power feeds for the under dash,( and the two 12ga act as a single 8 ga wire) and you're lightening the amp draw- the stock wires and feed throughs will do just fine if the connectors are clean and not melted. Choice is yours.

All the relays are continuous duty, with the exception of the Starter relay ( which isn't marked but has all the power feeding to it-) and the Ford Solenoid in the trunk. The Headlamps are 30-40 amp rated and the Voltage Regulator is 10 amps. It won't ever see that much but the Headlamps will draw @ 20A ( my best guess,since figured it out yet). ( lets see 4 - 55w bulbs = 220 watts/ 12 volts = 18 amps) so yes a 30 amp should give you a %50 margin of safety/ reliability.

You'll have to do the research on the fuses since I don't know what the proper ratings should be. With the links- they should either work or blow into oblivion. I never heard of them being spotty- but that doesn't mean it couldn't happen.

The wire feed through s: Not really necessary- you can if you want, but since the red and black become power feeds for the under dash,( and the two 12ga act as a single 8 ga wire) and you're lightening the amp draw- the stock wires and feed throughs will do just fine if the connectors are clean and not melted. Choice is yours.

4th generation B bodys- there is no substitute.

68 383, Street Demon 750, RPM top end,484/284/108 poo poo cam "-5 spd 4:10 SG, 4whl disk, Helwig Anti-Sway, Poly bushings,Firm Feel Box, HD Linkage, 1" t-bars, 7 leafs Springs

68 383, Street Demon 750, RPM top end,484/284/108 poo poo cam "-5 spd 4:10 SG, 4whl disk, Helwig Anti-Sway, Poly bushings,Firm Feel Box, HD Linkage, 1" t-bars, 7 leafs Springs

-

dangina

- GTX (RS)

- Posts: 380

- Joined: Sat Feb 12, 2011 12:28 am

- My Cars: 71 roadrunner

- Location: lethbridge, ab

Re: Solenoid for Trunk Mounted battery

that would be awesome! I'm liking this setup, adds to the one I have plus the headlight relays which will be especially useful as I will be upgrading to HID's. I checked out some of your photos, I like the black on black theme! do you have any full front pics of the wire mesh grill? always wondered how that would look

400 stroked to 470ci, 3:55 Eaton true trac, slightly upgraded suspension lol

BUILD THREAD!!!! http://www.protouringmopar.com/showthread.php?796-1971-Speedipus-Rex&highlight=speedipus

BUILD THREAD!!!! http://www.protouringmopar.com/showthread.php?796-1971-Speedipus-Rex&highlight=speedipus

-

71_bronze_gtx

- GTX (RS)

- Posts: 265

- Joined: Tue Jan 22, 2013 1:32 pm

- My Cars: 71 GTX

72 cuda repli-mod - Location: S. E. Michigan

Re: Solenoid for Trunk Mounted battery

The perspective of an electrical engineer who works in automotive - the one with the four letter name.

Ammeters themselves, if of good quality, are not a problem. BUT, the sizing of the wiring to and fro, and the quality and condition of connections is very important. The blade connectors used in the bulkhead disconnect for any high-current loads are marginal at best when new. After years of surface oxidation, vibration and expansion and contraction with temperature changes, they become very inadequate. The end result can be both poor charging and low voltage at various loads - especially those fed back out thru the bulkhead. I found I had only 10.3 volts on the "ignition" wire at the voltage regulator even though there was 12.7 volts at the battery (car not running). I put new #10 wire with soldered terminals directly from the starter relay to the ammeter and from the alternator B+ to the ammmeter. The ignition voltage came up to 11.8. That's still a bit low. It means that the connections between the ammeter and the ignition wire, including switch, bulkhead, etc. are less than ideal. All new harnesses is the best solution. Cleaning and reconditioning all the terminals might help some. If originality is not desired, go to bolted lug connections.

Note that if the 60 amp alternator option was on the '71 Satellites, the wiring to the ammeter bypasses the bulkhead disconnect (the same way I did it), and the alternator B+ wire is upsized from #12 to #8. The battery wire remains as #10.

The size of the cable from the battery to the starter is a bit marginal also. If moving a battery to the trunk, I would recommend sizing up 2 or 3 wire gage sizes from the standard #6 - to #2 or 0. Otherwise, cranking voltage will be low.

Every relay or battery disconnect along the way adds resistance which in turn lowers the cranking voltage. So if these are must have items make sure they are overkill in sizing. This applies more to relays than battery disconnects.

Back to ammeters: voltmeters are cheaper than ammeters, but they don't really indicate if the battery is discharging. Ideally, use both.

Ammeters themselves, if of good quality, are not a problem. BUT, the sizing of the wiring to and fro, and the quality and condition of connections is very important. The blade connectors used in the bulkhead disconnect for any high-current loads are marginal at best when new. After years of surface oxidation, vibration and expansion and contraction with temperature changes, they become very inadequate. The end result can be both poor charging and low voltage at various loads - especially those fed back out thru the bulkhead. I found I had only 10.3 volts on the "ignition" wire at the voltage regulator even though there was 12.7 volts at the battery (car not running). I put new #10 wire with soldered terminals directly from the starter relay to the ammeter and from the alternator B+ to the ammmeter. The ignition voltage came up to 11.8. That's still a bit low. It means that the connections between the ammeter and the ignition wire, including switch, bulkhead, etc. are less than ideal. All new harnesses is the best solution. Cleaning and reconditioning all the terminals might help some. If originality is not desired, go to bolted lug connections.

Note that if the 60 amp alternator option was on the '71 Satellites, the wiring to the ammeter bypasses the bulkhead disconnect (the same way I did it), and the alternator B+ wire is upsized from #12 to #8. The battery wire remains as #10.

The size of the cable from the battery to the starter is a bit marginal also. If moving a battery to the trunk, I would recommend sizing up 2 or 3 wire gage sizes from the standard #6 - to #2 or 0. Otherwise, cranking voltage will be low.

Every relay or battery disconnect along the way adds resistance which in turn lowers the cranking voltage. So if these are must have items make sure they are overkill in sizing. This applies more to relays than battery disconnects.

Back to ammeters: voltmeters are cheaper than ammeters, but they don't really indicate if the battery is discharging. Ideally, use both.

- road chicken

- GTX (RS)

- Posts: 660

- Joined: Thu Oct 09, 2003 11:21 pm

- Location: SE WI

Re: Solenoid for Trunk Mounted battery

dangina wrote: I checked out some of your photos, I like the black on black theme! do you have any full front pics of the wire mesh grill? always wondered how that would look

I added some to the photobucket library- feel free. It kinda gets lost, you see a haze but the eye doesn't know to focus on it or the grill so it blurrs. The only place it is "clearly there" is over the signals and that fades as you get off center. I might be going blind too.. so

4th generation B bodys- there is no substitute.

68 383, Street Demon 750, RPM top end,484/284/108 poo poo cam "-5 spd 4:10 SG, 4whl disk, Helwig Anti-Sway, Poly bushings,Firm Feel Box, HD Linkage, 1" t-bars, 7 leafs Springs

68 383, Street Demon 750, RPM top end,484/284/108 poo poo cam "-5 spd 4:10 SG, 4whl disk, Helwig Anti-Sway, Poly bushings,Firm Feel Box, HD Linkage, 1" t-bars, 7 leafs Springs

-

dangina

- GTX (RS)

- Posts: 380

- Joined: Sat Feb 12, 2011 12:28 am

- My Cars: 71 roadrunner

- Location: lethbridge, ab

Re: Solenoid for Trunk Mounted battery

very cool, I do like the look of it, as a bonus it probably catches all the bugs and protects the grill

another question I was thinking about is the ford solenoid. Do you have or know of the part#? Everyone refers to it but I can't find a part # anywhere

another question I was thinking about is the ford solenoid. Do you have or know of the part#? Everyone refers to it but I can't find a part # anywhere

400 stroked to 470ci, 3:55 Eaton true trac, slightly upgraded suspension lol

BUILD THREAD!!!! http://www.protouringmopar.com/showthread.php?796-1971-Speedipus-Rex&highlight=speedipus

BUILD THREAD!!!! http://www.protouringmopar.com/showthread.php?796-1971-Speedipus-Rex&highlight=speedipus

- road chicken

- GTX (RS)

- Posts: 660

- Joined: Thu Oct 09, 2003 11:21 pm

- Location: SE WI

Re: Solenoid for Trunk Mounted battery

[quote="71_bronze_gtx"]The perspective of an electrical engineer who works in automotive - the one with the four letter name.

You work for FIAT?! All true, the connections are the killers. If the battery stays up front, where the voltage regulator can "see" it, those fixes go along way.

All true, the connections are the killers. If the battery stays up front, where the voltage regulator can "see" it, those fixes go along way.

Once I put the battery in back the stock harness locations just weren't getting it done. I grabbed my Fluke and swiped a Hioki Clamp from work and went to town. The factory system wasn't seeing enough load from the battery. On long trips, ( with the 6 ga feed to the battery, soldered, lugged) it trickle charged enough to keep up. The short trips or rallyes with 20 miles between stops- not cool. By the third stop it was noticeable, by #6 I knew I'd be pop-starting #7. Embarrassing! I looked over a few sites, saw what I was seeing on the meters and put this together and wired it in. It really is the cats behind imho. Everything works great and is noticeably better than the stock system. I used to have alt whine, pops in the stereo from the turn signal dropping the system voltage- just gremlins all over the place. Once I wired in the modfications to this set-up it all went away. 13.5v at the relay post, 12.8v at the battery. All the relays I use are 40 amp units, ( seems to be the popular size and price) so those are no problem, and the main feed to the starter is "0"ga. I'll call that out on the drawing up grade. I could see a shunt type amp meter, but the factory unit is proven to cause issues so that puppy was getting 86'd, its just too much of a risk with how much I use mine. Reading the voltmeter from the distribution point will tell you if you have problems. If it drops from 13.5 to 12, somethings amiss. They can tell you the same thing in a different way.

I looked over a few sites, saw what I was seeing on the meters and put this together and wired it in. It really is the cats behind imho. Everything works great and is noticeably better than the stock system. I used to have alt whine, pops in the stereo from the turn signal dropping the system voltage- just gremlins all over the place. Once I wired in the modfications to this set-up it all went away. 13.5v at the relay post, 12.8v at the battery. All the relays I use are 40 amp units, ( seems to be the popular size and price) so those are no problem, and the main feed to the starter is "0"ga. I'll call that out on the drawing up grade. I could see a shunt type amp meter, but the factory unit is proven to cause issues so that puppy was getting 86'd, its just too much of a risk with how much I use mine. Reading the voltmeter from the distribution point will tell you if you have problems. If it drops from 13.5 to 12, somethings amiss. They can tell you the same thing in a different way.

You work for FIAT?!

Once I put the battery in back the stock harness locations just weren't getting it done. I grabbed my Fluke and swiped a Hioki Clamp from work and went to town. The factory system wasn't seeing enough load from the battery. On long trips, ( with the 6 ga feed to the battery, soldered, lugged) it trickle charged enough to keep up. The short trips or rallyes with 20 miles between stops- not cool. By the third stop it was noticeable, by #6 I knew I'd be pop-starting #7. Embarrassing!

4th generation B bodys- there is no substitute.

68 383, Street Demon 750, RPM top end,484/284/108 poo poo cam "-5 spd 4:10 SG, 4whl disk, Helwig Anti-Sway, Poly bushings,Firm Feel Box, HD Linkage, 1" t-bars, 7 leafs Springs

68 383, Street Demon 750, RPM top end,484/284/108 poo poo cam "-5 spd 4:10 SG, 4whl disk, Helwig Anti-Sway, Poly bushings,Firm Feel Box, HD Linkage, 1" t-bars, 7 leafs Springs

- road chicken

- GTX (RS)

- Posts: 660

- Joined: Thu Oct 09, 2003 11:21 pm

- Location: SE WI

Re: Solenoid for Trunk Mounted battery

dangina wrote:very cool, I do like the look of it, as a bonus it probably catches all the bugs and protects the grill

another question I was thinking about is the ford solenoid. Do you have or know of the part#? Everyone refers to it but I can't find a part # anywhere

Yes, There is plenty of bugs smooged into, and stone chips in that paint-in fact I might freshen that up this year too. The kid next door gets a nature lesson when I get back from a road trip

The Ford solenoid I use is for spec'd for a 1973 Ford F350- 460 cid. Rock Auto has the "Good" one for $9 plus shipping, Part number "AIRTEX / WELLS Part # 1M1030" I'm sure you can pick one up local no problem. BUT Even when you crimp the lugs- Solder them too- makes a huge difference in V-drop and current carrying capability. Low resistance is paramount. I know I sound like broken record, but soldering the connections is that important- even the factory system would benefit.

4th generation B bodys- there is no substitute.

68 383, Street Demon 750, RPM top end,484/284/108 poo poo cam "-5 spd 4:10 SG, 4whl disk, Helwig Anti-Sway, Poly bushings,Firm Feel Box, HD Linkage, 1" t-bars, 7 leafs Springs

68 383, Street Demon 750, RPM top end,484/284/108 poo poo cam "-5 spd 4:10 SG, 4whl disk, Helwig Anti-Sway, Poly bushings,Firm Feel Box, HD Linkage, 1" t-bars, 7 leafs Springs

-

71_bronze_gtx

- GTX (RS)

- Posts: 265

- Joined: Tue Jan 22, 2013 1:32 pm

- My Cars: 71 GTX

72 cuda repli-mod - Location: S. E. Michigan

Re: Solenoid for Trunk Mounted battery

Yeah, I'm going to have to go ahead and sort of disagree with this.road chicken wrote:If the battery stays up front, where the voltage regulator can "see" it, those fixes go along way.

The regulator "sees" the overall system voltage as determined by the alternator output and the battery voltage, all of that dependent on how much electrical load there is, and also dependent on the condition of the connections between the ammeter circuit and the regulator wiring and ground connection. The distance of the battery is not a factor IF the wire size is big enough and the connections are good. In general, the lower the "seen" voltage at the regulator "ignition" terminal, the more the alternator output is raised by the regulator. This is done by raising the alternator "field" voltage. The field winding of the alternator connects to the "ignition" voltage (nominally +12 V.) and the regulator, so technically, the regulator lowers the voltage on it's "field" terminal to increase the overall voltage on the alternator field.

The B+ terminal of the alternator provides the "ignition voltage" when the car is running, BUT it may be reduced by smallish wire gage and poor connections back out through the bulkhead connectors. Also, the state of battery charge will affect it. Typically, right after a car is started, you'll see the ammeter move high into the charge side and then come back down to just above center. A low, but steady current is going through the battery even though it is fully charged, and the system voltage typically levels off at 13+ volts.

- road chicken

- GTX (RS)

- Posts: 660

- Joined: Thu Oct 09, 2003 11:21 pm

- Location: SE WI

Re: Solenoid for Trunk Mounted battery

We'll just have to disagree then. What I do know is that my system works reliably with the battery in back after the factory setup didn't, even with all the connections cleaned up and in optimum shape. What is theory doesn't always work in application. Where the regulator is placed in the system is of paramount importance in it's ability to get the signal it needs to do it's job properly. 20 years in R&D working on Naval Power System for Nuclear Subs, Touch Screens, Power Tools and few others, gave me a little background in electrical distribution and loading, as well.

4th generation B bodys- there is no substitute.

68 383, Street Demon 750, RPM top end,484/284/108 poo poo cam "-5 spd 4:10 SG, 4whl disk, Helwig Anti-Sway, Poly bushings,Firm Feel Box, HD Linkage, 1" t-bars, 7 leafs Springs

68 383, Street Demon 750, RPM top end,484/284/108 poo poo cam "-5 spd 4:10 SG, 4whl disk, Helwig Anti-Sway, Poly bushings,Firm Feel Box, HD Linkage, 1" t-bars, 7 leafs Springs

-

dangina

- GTX (RS)

- Posts: 380

- Joined: Sat Feb 12, 2011 12:28 am

- My Cars: 71 roadrunner

- Location: lethbridge, ab

Re: Solenoid for Trunk Mounted battery

did you make this bigger by chance??!!

I found this website that I will be using their feed through connectors:

http://www.perfprotech.com/feed-through ... duct/35341

smallest hole to drill I found, everyone elses you need to drill a 1 1/4" hole which I think is too big

I found this website that I will be using their feed through connectors:

http://www.perfprotech.com/feed-through ... duct/35341

smallest hole to drill I found, everyone elses you need to drill a 1 1/4" hole which I think is too big

400 stroked to 470ci, 3:55 Eaton true trac, slightly upgraded suspension lol

BUILD THREAD!!!! http://www.protouringmopar.com/showthread.php?796-1971-Speedipus-Rex&highlight=speedipus

BUILD THREAD!!!! http://www.protouringmopar.com/showthread.php?796-1971-Speedipus-Rex&highlight=speedipus

- road chicken

- GTX (RS)

- Posts: 660

- Joined: Thu Oct 09, 2003 11:21 pm

- Location: SE WI

Re: Solenoid for Trunk Mounted battery

Sorry- Not yet.  I've been spinning wrenches on the chicken in the freetime

I've been spinning wrenches on the chicken in the freetime  I'm hoping to get back on it Saturday- so check back early next week .

I'm hoping to get back on it Saturday- so check back early next week .

Those connectors should work for any circuit but the 0ga starter powerfeed. Marine stuff is always a bit more stout.Considering what its protecting- well spent I brought 0ga up the drivers side wire way (in a split loom for extra protection) and up the firewall. There is a 1" plug just to the outside that comes out just under the hood hinge. Worked perfect for that 0g starter wire, with a hd rubber grommet.

Those connectors should work for any circuit but the 0ga starter powerfeed. Marine stuff is always a bit more stout.Considering what its protecting- well spent I brought 0ga up the drivers side wire way (in a split loom for extra protection) and up the firewall. There is a 1" plug just to the outside that comes out just under the hood hinge. Worked perfect for that 0g starter wire, with a hd rubber grommet.

4th generation B bodys- there is no substitute.

68 383, Street Demon 750, RPM top end,484/284/108 poo poo cam "-5 spd 4:10 SG, 4whl disk, Helwig Anti-Sway, Poly bushings,Firm Feel Box, HD Linkage, 1" t-bars, 7 leafs Springs

68 383, Street Demon 750, RPM top end,484/284/108 poo poo cam "-5 spd 4:10 SG, 4whl disk, Helwig Anti-Sway, Poly bushings,Firm Feel Box, HD Linkage, 1" t-bars, 7 leafs Springs